PASSION FOR

NATURAL PRODUCTS

Competence, experience and innovation in the production of composites with sustainable materials

Madera Fiber Technologies is located in Porriño, Spain in close proximity to Vigo. The company is specialized in the production and supply of composite parts made from natural fibers such as wood, flax, kenaf, hemp …

Madera Fiber Technologies provides its innovative solutions to a wide range of customers from various industries and regions, especially the automotive and furniture industries.

High-end technology products with excellent properties

Our products stand out for its excellent mechanical properties such as stiffness and stability, good insulation properties and low density, making them highly attractive for industrial use.

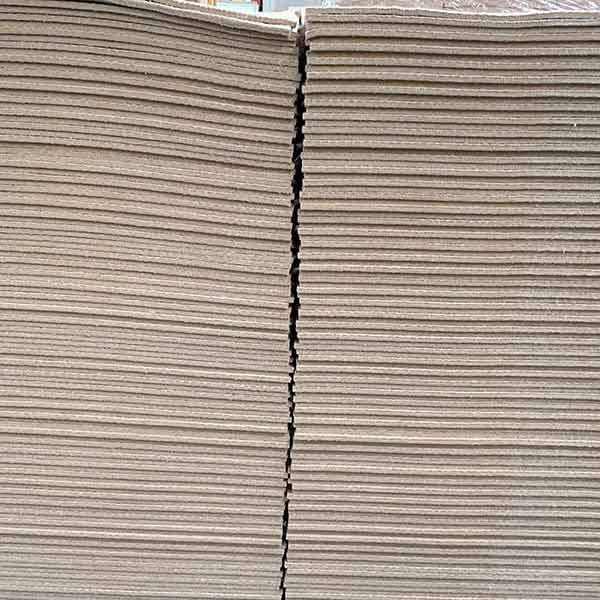

WF / NFPP Mats

Our composites are made from natural fibers of wood, flax, hemp and kenaf mixed with synthetic fibers such as polypropylene and polyester that allow them to get great properties for its different applications. These materials are used in hot or cold press processes. This allows us to offer different customized solutions in their processability and final properties

Pressed Parts

We apply different types of hot presses (400-600 ton), which allows us to produce semi-finished & finished products for our customers. For the automotive industry, we can produce a wide range of parts for the interior as bolster-inserts, armrest, top roll, door panels carriers.

Covered Parts

We can produce end parts in a one-shot process. These parts can be made in dilour, PVC or fabric. For the parts that have been previously pressed in our hot press department, we can produce end products by a coating process in our vertical presses or by a manual process.

Innovative solutions with many benefits

Our recipe for success is based on the combination of natural fibers with polypropylene or other thermoset binders.

Renewable raw materials

Madera Fiber Technologies offers solutions for components that contribute to the lightening or reinforcement of car interior trim as well as for furniture and the building sector.

These products are an environmentally friendly alternative to the conventionally used like plastic injection molding.

Key properties

- Weight reduction: Low density that means an important weight reduction in comparison with other materials (i.e.: 1450 g/m2 wood vs 2500 g/m2 PP)

- Noise insulator: natural fibers absorb acoustic vibrations and improve the tortuosity of products.

- Heat insulator: Low thermal conductivity (30 times less than plastic)

- Shape and dimensional stability

- Surface finish of WF carriers allows to work with fabric or leather without any kind of foam or intermediate sheet

- Shorter lead-time for product launching or modification

- Sustainability: wood,flax,kenaf … are renewable natural resources

Innovative solutions

We are working to develop products to meet the new demands of our customers in terms of lightness, reduction of environmental impact, and processability. We have equipments that allows us to format our products and perform tests in order to be able to advise and provide quality technical support to our customers.

Our solutions for versatile markets

Automotive

Madera offers solutions for components in the entire vehicle interior that will contribute to the lightening or reinforcement of certain interior trim parts

Furniture

Because of its versatility and its physical and mechanical resistance, Madera's wood fiber solutions have been used in the furniture industry for years.

Logistics & packaging

In the field of logistics and packaging, We can provide a wide range of durable products for packaging (trays, positioners, boxes …)

Acoustic & thermal protection

Our solutions are excellent for the production of interior cladding - not only because of its light weight, but also because of the many possibilities for finishing.

Our references

With our modern and versatile machinery, we are able to offer our customers a wide range of products in a variety of industries.

Promoting innovative thinking to bring the performance of natural fibers into new applications.

Competence and experience for successful solutions

Customer orientation

We put our customers at the centre of everything we do and create trusting and sustainable partnerships.

Great Experience

With our roughly 30 years of experience, we offer customers an extensive portfolio of services and an extensive experience in the develop of new products and process.

Continuous Improvement

We are committed to environmental preservation, social responsibility and to fulfilling our customers’ requirements. ISO9001 & IATF16949 & ISO 14001 Certified

Highest flexibility

Due to our high flexibility and qualification we can react in short terms to the wishes and needs of our customers

Aligned with the regulations

As a reliable partner we are used to work the standards of our customers. We are committed to environmental preservation, social responsibility and to fulfilling our customers’ requirements

Qualified Team

We offer our customers all our good practice and experience in production and development

Madera – tradition combined with future-oriented strategies

Madera Fiber Technologies supply technical solutions based on composites made with natural fibers such as wood, kenaf, flax … for numerous applications in different industrial markets and especially for the automotive & furniture sector.

The company was founded in 1987 by the German LIGNOTOCK group. Later, it was sold to Sommer Allibert and then to Faurecia, until reaching our days as its own entity, Madera Fiber Technologies SL, owned by the investment group Callista. Initially, the main activity of the plant was the production of wood fiber mats. We have incorporated new production lines that allow us to also manufacture products from other natural fiber such as flax, kenaf, hemp …

In addition to the production of the mat, the plant has a large number of presses that allow us to carry out the press and covering processes to offer our clients semi-finished or finished products.

Further information on quality policy, sustainability and certification

- Quality policy (pdf)

- Sustainability policy (pdf)

- We have the IATF certification (pdf) and the ISO 9001:2015 certification (pdf)

Contact – get in touch with us.

Contact

-

Polígono Industrial As Gándaras Parcela 205

36400 – Porriño (Pontevedra) Spain - +34 986 344 036

- info@madera-fiber.com